PROFESSIONAL Crushing & Screening Services

Mobile and fixed plants for projects of all scales – from residential renovations to mine-site operations

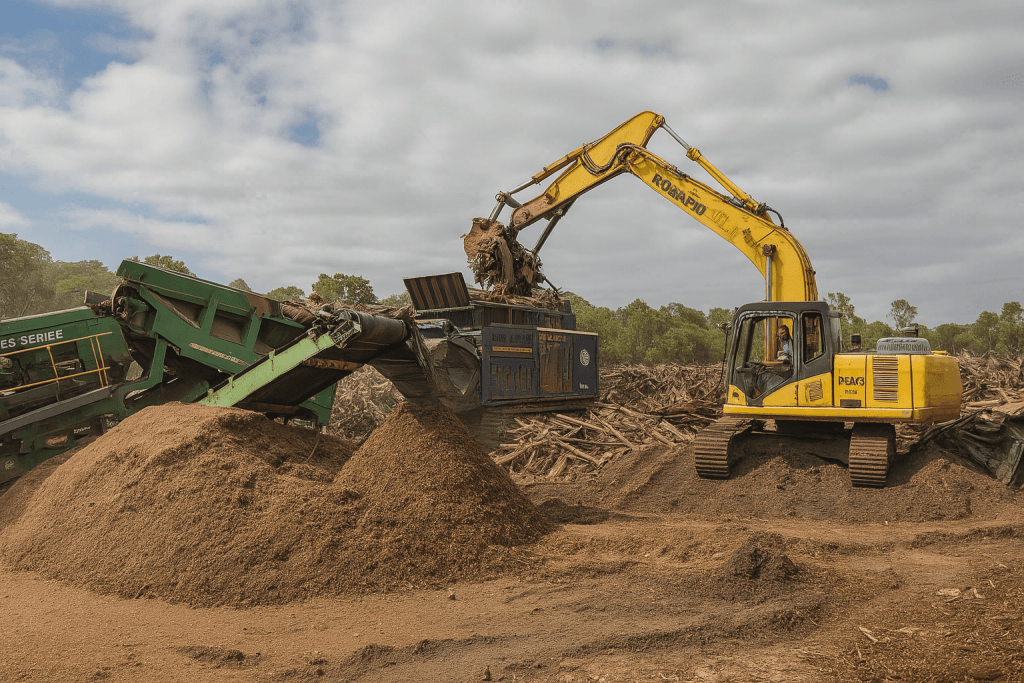

PRR delivers licensed, end-to-end crushing and screening services across Western Australia, combining our 50+ years of expertise with WA’s only accredited Material Recovery Facility (MRF) to transform waste and virgin materials into high-quality, specification-grade aggregates. From recycling operations to quarry applications—and everything in between—PRR delivers fast, efficient, and cost-effective crushing and screening services, available for wet or dry hire. We deliver reliable mobile and fixed crushing and screening services across Western Australia—from urban demolition sites in Perth to large-scale regional mining operations in Karratha, Kalgoorlie, Geraldton, and beyond.

- Mobile & Fixed Plants: Rapid deployment across WA for projects of all scales – from urban demolition to remote mine sites

- 1M+ Tonnes Annual Capacity: Processing concrete, brick, rock, and more

- Real-Time Material Tracking: Waste Edge software for transparent reporting

Why Peel Resource Recovery?

Unmatched Expertise

- WA’s only accredited MRF for construction & demolition waste

- Class 2 Demolition License (WAD 234) for full-scope site clearance

- 50+ years in civil contracting & material processing

Sustainable Results

♻️ 90% landfill diversion rate

📊 Real-time Waste Edge tracking for transparent reporting

🌿 Closed-loop system: Your waste becomes your resources

End-to-End Service

- On-site crushing at your location

- Material testing & quality certification

- Haulage via our skip bin & hook lift fleet

Skilled Workforce

Licensed operators with hazardous material training

Onsite Crushing and Screening

Save Time and Haulage Costs – Optimize your project with crushing and screening services that provide efficient, cost-saving solutions right at your site. Our onsite crushing eliminates the need for hauling, drastically reducing transportation costs and project delays. Whether you’re working in construction, demolition, mining, or quarrying, our mobile crushing and screening units ensure that your material processing is handled swiftly and effectively.

By choosing onsite crushing and screening, you avoid the hassle and expense of transporting materials to distant facilities. We bring state-of-the-art equipment directly to your location, helping you save both time and money. Our services include crushing a variety of materials, including concrete, asphalt, and rocks.

Key Benefits of Onsite Crushing and Screening:

- Cost Reduction: Save significantly on haulage costs by processing materials at your site.

- Increased Efficiency: Speed up project timelines with faster material processing onsite.

- Customizable Solutions: Our mobile crushers and screening equipment are flexible and adaptable for all project needs.

- Eco-Friendly: Onsite crushing helps reduce carbon emissions by eliminating the need for long-distance transportation.

With a highly skilled team and industry-standard equipment, we guarantee efficient, high-quality crushing and screening services. Trust us to enhance your project’s performance with the best onsite solutions.

Offsite Crushing and Screening

If onsite access is limited or you’re looking for a more cost-effective solution, we also offer crushing services at our fully licensed resource recovery facility. You can transport bulk materials to us, and we’ll handle:

- Efficient material separation

- High-capacity crushing and screening

- Recycling into reusable aggregates

This gives you flexibility to choose what works best for your operation — onsite crushing for convenience, or facility-based processing for large-scale recovery and recycling.

Key Benefits of Offsite Crushing and SCREENING:

- Access to Advanced Crushing Technology: Utilizing state-of-the-art mobile crushing and screening equipment ensures optimal material handling and high-quality results.

- High-Volume Crushing Efficiency: Ideal for large-scale projects, offsite crushing enables the processing of significant quantities of material quickly and efficiently.

- Consistent Material Quality: Crushing services performed offsite ensure precise material sizing and uniformity, meeting your project’s specifications.

- Reduced Onsite Disruption: Offsite crushing keeps your construction or demolition site free from the noise, dust, and logistical challenges of onsite crushing.

With our offsite crushing services, we offer scalable, efficient, and high-quality material processing, ideal for concrete crushing, rock crushing, and asphalt crushing projects.

Our Crushing and Screening Fleet

KLEEMANN MR 130 EVO2

J50 Jaw Crusher

I44 Impact Crusher

Vertical Shaft Impact -V80 Crusher

S130

McCloskey TS4065 Tracked Stacker

Statewide Coverage: Crushing & Screening Anywhere in Western Australia

vWe proudly offer our services throughout Western Australia, including high-demand areas for material processing and tyre disposal like:

- Perth – high construction volume, ideal for urban crushing jobs

- Kwinana – known for industrial and port activity

- Kalgoorlie – significant mining sector needs

- Geraldton – high demand for sustainable remediation

- Karratha & Port Hedland – high-growth mining and resource hubs

- Bunbury & Albany – active construction and recycling zones,

VERSATILE CRUSHING AND SCREENING SOLUTIONS FOR EVERY NEED

Frequently Asked Questions

Some frequently asked questions about the service that you may have questions about

What materials can PRR process?

• Demolition waste (asbestos-managed)

• Hard rock (mine sites)

• Gravel & quarry materials

• Railway ballast & agricultural lime (aglime

Are your recycled products compliant with regulations?

• WALGA specifications for road base & construction

• DWER licensing (L7060/1997/13)

• Asbestos safety standards (WARA 1362 licensed)

Do you offer on-site mobile crushing?

• Track-mounted jaw/impact crushers

• Trommel screens for precise grading

• Electromagnets for metal recovery

• WA-wide service (urban & remote sites)

How much material can PRR process annually?

• WA’s only accredited C&D Material Recovery Facility (MRF)

• Mobile plants for project-specific needs

What’s your landfill diversion rate?

• 0-20mm crushed concrete

• Screened sand (0-10mm)

• Recycled road base

How do you handle asbestos-contaminated materials?

• Double-bagged disposal at our Class 1 Landfill

• Real-time tracking via Waste Edge software

Can you provide material test reports?

• Particle size distribution analysis

• Contamination testing

• WALGA compliance documentation

Do you service residential projects?

• Skip bin deliveries (4m³–30m³)

• Small-scale concrete recycling

• Clean fill processing

What industries do you serve?

Do you provide mobile crushing and screening services across Western Australia?

How can I request a quote or site assessment?

PEEL RESOURCE RECOVERY CAPABILITY STATEMENT